Lego: The toy with no end-of-life

Such is life: You’re about to finish the battlements on your Police Pirate Space Castle and you’re one Lego brick short. Fortunately, you can use any brick produced since 1958. Lego was standardised before the metric system left Europe and a decade before shipping containers would be similarly settled.

Lego is the most environmentally friendly toy on the market. It literally has no end-of-life. It doesn’t break, it doesn’t wear out, and there’s a ready market for it as an alternative to the trash.

Every brick that Lego make is another one in the global stockpile - now 90 bricks for every person on the planet. And despite moulding plastic non-stop since the 1950’s, the price of Lego remains as buoyant as ever - both new and used. I honestly don’t know where all that Lego goes, but we can say that the amount being landfilled is effectively zero.

Think how unique this is among toys with their fleeting licensing deals, brittle and irreparable plastic structures, and zero resale value.

Getting greener

The LEGO Group made a commitment to run its operations on 100% renewable energy by 2020. And it’s on course - in 2013 it invested €400m into a North Sea windfarm which is now 50% operational.

They have also put things in smaller boxes, although boxes are often still about twice the size they need to be. I understand: The size of the box directly equates to the number of hours of tranquility a parent is going to enjoy.

But the company has a problem getting fully green: 90% of carbon emissions lie in its supply chain, and over 30% is from the raw material that goes into Lego bricks: crude oil.

Lego used 68,000 tonnes of plastic pellets in 2013.

The company plans to come up with a sustainable alternative material for bricks by 2030. LEGO bricks are made from a type of plastic called acrylonitrile butadiene styrene or ABS. It can be recycled, but that’s irrelevant because only a complete idiot would recycle Lego.

Any replacement material will have to match some formidable properties:

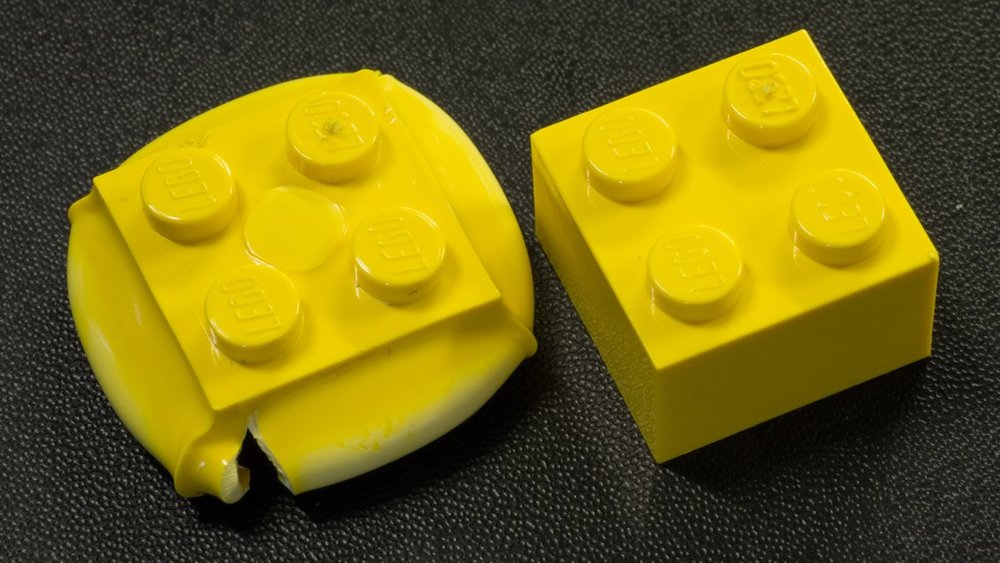

- Strength. A single 2x2 brick can support 430kg.

- Durability. Lego is indestructible. (Citation: Extensive personal crash testing of various Lego vehicles.) Dedicated research shows that two lego bricks can be joined and separated 37,112 times before they lose their grip to each other.

- Clutch power. This is a critical property that sets Lego apart from its cheap clones (the last Lego patent expired in 1989.) There is a fine tolerance that lets a block be easily joined, remain attached, and then be disassembled without tools.

- Colourfastness. There are 23 colors of lego brick. They shouldn’t fade.

The LEGO Economy

Raw

Lego’s raw material, ABS plastic pellets, cost $3 per kg when bought in huge bulk.

New

Lego increase the value of that raw material by at least 20x when it lands on the shelf. The best value set on a piece-by-piece basis is the Detective’s Office (epic in its own right). It contains 2,262 pieces and weighs 2.6kg. So Lego transform $7.80 worth of pellets into an RRP of $160. New lego costs a minimum of $60 per kg.

Used

Once it’s been built, dismantled, jumbled up chewed and the instructions eaten, it might get put into plastic bags and flogged on eBay. Used Lego, unsorted in bags, sells for $10 to $20 per kg.

Most used sets sell for around 70-80% of their RRP. Some sets become collectible and then sell for a fortune: like the Ultimate Collector’s Millennium Falcon which was $500 new and now sells for $1,500 to $2,000. Or any sort of monorail.

This means that once a Lego brick has been moulded it will never be worth less than 6 times the value of raw material that went into it. This has to be unique among mass market products.